Since entering the new century, energy has become one of the focus of the world. In the era of extensive production, energy problems are not very prominent, enterprises always focus on expanding production, as long as the output will have profits. And now the relationship between energy and profit becomes more and more close, petrochemical enterprises to carry out energy saving and consumption reduction is the fundamental measure to alleviate the contradiction of energy constraints of enterprises, but also to enhance the competitiveness of enterprises and achieve the sustainable development of chemical enterprises.

The high temperature pipeline and refining equipment of petrochemical enterprises are generally 200℃-650℃, while the pipeline that contacts the heat source is even as high as 1000℃, at the same time, the operation of the equipment is accompanied by low frequency mechanical vibration.

In such a harsh production environment...

How to ensure that the high temperature stability of the insulation layer does not decay when the equipment is in normal production?

How to ensure that the equipment does not affect the normal production due to the failure of the insulation layer "running, dropping, leaking "? How to reduce the frequency of insulation layer replacement, so as to prolong the maintenance cycle of equipment and achieve the goal of stable production and efficiency? How to ensure that workers do not operate because of the sudden failure of insulation layer life-threatening?

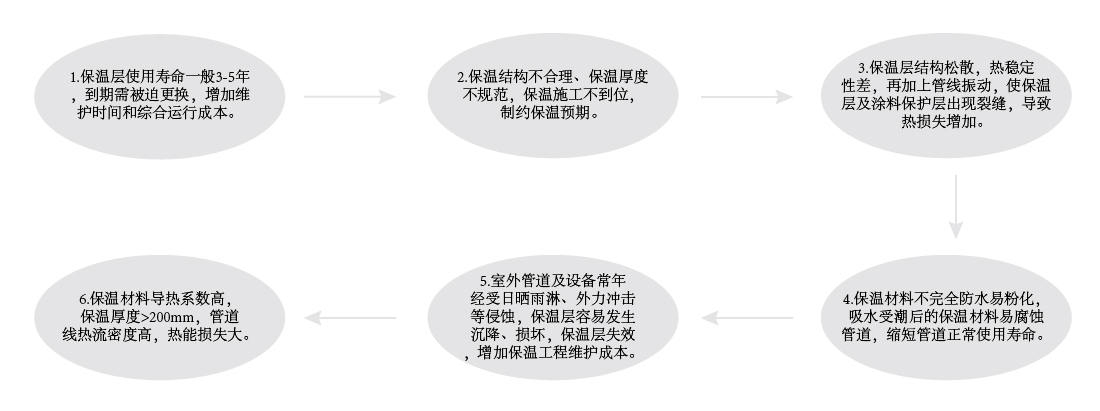

Current Situation of Traditional Insulation Engineering

Chinese Resources ®zhongkegel HT Insulation and Insulation felt Perfectly Solve the above problems

thermal conductivity of thermal insulation felt is extremely low, the thermal insulation effect is 2-5 times that of traditional insulation material, thus greatly reducing the thickness of insulation layer, and ensuring the same insulation effect only needs 1/2-1/5 of the thickness of traditional insulation material.

material 99% hydrophobic ratio and A1 grade completely non-combustible characteristics, it can be said that water and fire do not invade, adapt to bad working conditions.

the whole structure is stable, the structure is easy to wrap and fit the equipment, at the same time, its sound insulation and vibration absorption performance is excellent, can protect the equipment in all directions and reduce the environmental noise from the source.

the overall quality of light and soft, can be cut with the United States knife, not afraid of wild construction, easy to use, shorten the construction cycle, to ensure the construction progress as soon as possible.

high temperature stability, insulation effect does not decay, theoretical life of 20 years, reduce the maintenance cost of insulation engineering. In the same industry the only non-powder (visual), performance indicators leading the world, so as to ensure the excellent properties of materials and protect the construction environment.

Scene extension: steel, non-ferrous metals, building materials, chemical industry, coal, electricity (cogeneration of heat and power, waste (sludge) incineration power plant), oil, cement and other high-energy enterprises